Tsoelo-pele ea Lipatlisiso mabapi le Li-Polyurethane tse sa Isocyanate

Ho tloha ha li hlahisoa ka 1937, thepa ea polyurethane (PU) e se e sebelisoa haholo makaleng a fapaneng ho kenyeletsoa lipalangoang, kaho, lik'hemik'hale tsa peterole, masela, boenjiniere ba mechini le motlakase, lifofane, tlhokomelo ea bophelo bo botle le temo. Lisebelisoa tsena li sebelisoa ka mefuta e kang polasetiki ea foam, likhoele, li-elastomer, lintho tse thibelang metsi, letlalo la maiketsetso, liphahlo, likhomaretsi, thepa ea ho betla le lisebelisoa tsa bongaka. PU ea setso e entsoe haholo-holo ho tsoa ho li-isocyanate tse peli kapa ho feta hammoho le li-polyol tse kholo le li-extender tse nyane tsa ketane ea limolek'hule. Leha ho le joalo, chefo ea tlhaho ea li-isocyanate e baka likotsi tse kholo bophelong ba batho le tikolohong; ho feta moo hangata li tsoa ho phosgene - e leng selelekela se chefo haholo - le thepa e tala e tsamaellanang le eona ea amine.

Ka lebaka la boiteko ba indasteri ea lik'hemik'hale ea mehleng ena ba ho batla mekhoa ea nts'etsopele e tala le e tsitsitseng, bafuputsi ba ntse ba tsepamisa maikutlo haholoanyane ho nkeleng li-isocyanate sebaka ka mehloli e sireletsang tikoloho ha ba ntse ba hlahloba litsela tse ncha tsa tlhahiso bakeng sa li-polyurethane tse seng tsa isocyanate (NIPU). Pampiri ena e hlahisa litsela tsa ho lokisa NIPU ha e ntse e hlahloba tsoelo-pele mefuteng e fapaneng ea li-NIPU le ho buisana ka menyetla ea tsona ea bokamoso ho fana ka litšupiso bakeng sa lipatlisiso tse ling.

1 Ho kopanngoa ha Polyurethanes e seng ea Isocyanate

Tlhahiso ea pele ea metsoako ea carbamate e boima bo tlase ba limolek'hule e sebelisang li-carbonate tsa monocyclic tse kopantsoeng le li-diamine tsa aliphatic e etsahetse linaheng tse ling lilemong tsa bo-1950—e leng se tšoaeang motsotso oa bohlokoa ho ea ho synthesis ea polyurethane e seng isocyanate. Hona joale ho na le mekhoa e 'meli ea mantlha ea ho hlahisa NIPU: Ea pele e kenyelletsa liketso tsa ho eketsa butle-butle lipakeng tsa li-carbonate tsa binary cyclic le li-amine tsa binary; ea bobeli e kenyelletsa liketso tsa polycondensation tse kenyelletsang li-intermediate tsa diurethane hammoho le li-diols tse nolofalletsang phapanyetsano ea sebopeho ka har'a li-carbamate. Li-intermediate tsa Diamarboxylate li ka fumanoa ka litsela tsa cyclic carbonate kapa dimethyl carbonate (DMC); ha e le hantle mekhoa eohle e arabela ka lihlopha tsa carbonic acid tse hlahisang mesebetsi ea carbamate.

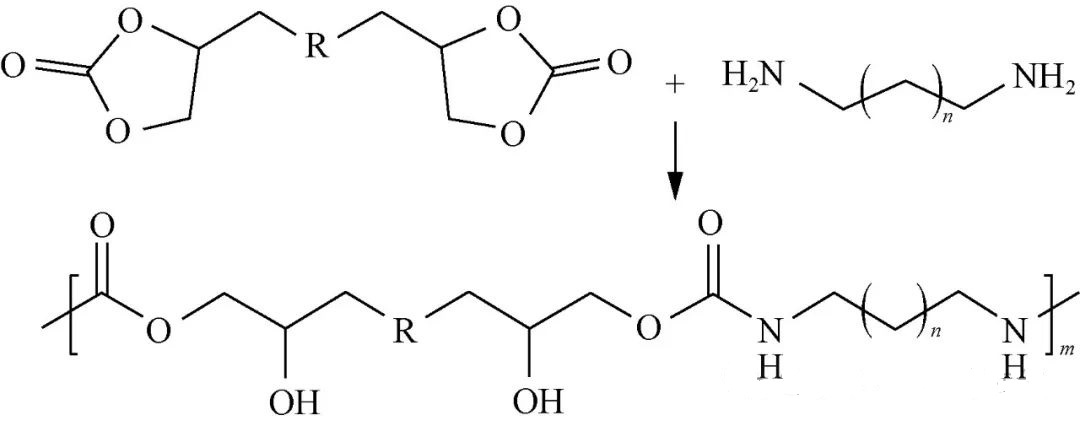

Likarolo tse latelang li hlalosa mekhoa e meraro e fapaneng ea ho kopanya polyurethane ntle le ho sebelisa isocyanate.

1.1 Tsela ea Binary Cyclic Carbonate

NIPU e ka kopanngoa ka ho eketsa mehato e kenyeletsang binary cyclic carbonate e kopantsoeng le binary amine joalo ka ha ho bontšitsoe ho Setšoantšo sa 1.

Ka lebaka la lihlopha tse ngata tsa hydroxyl tse teng ka har'a li-unit tse pheta-phetoang ho latela sebopeho sa eona se seholo sa ketane mokhoa ona hangata o hlahisa seo ho thoeng ke polyβ-hydroxyl polyurethane (PHU). Leitsch et al., ba thehile letoto la li-PHU tsa polyether tse sebelisang li-polyether tse felisitsoeng ke cyclic carbonate hammoho le li-amine tsa binary hammoho le limolek'hule tse nyane tse nkiloeng ho li-carbonate tsa binary cyclic - ba bapisa tsena le mekhoa ea setso e sebelisoang ho lokisa li-PU tsa polyether. Liphuputso tsa bona li bontšitse hore lihlopha tsa hydroxyl ka har'a li-PHU li theha maqhama a haedrojene habonolo le liathomo tsa naetrojene/oksijene tse fumanehang ka har'a likarolo tse bonolo/tse thata; phapang lipakeng tsa likarolo tse bonolo le eona e susumetsa boitšoaro ba ho kopanya haedrojene hammoho le maemo a karohano ea microphase ao hamorao a amang litšobotsi tsa ts'ebetso ka kakaretso.

Hangata e etsoa ka tlase ho mocheso o fetang 100 °C tsela ena ha e hlahise lihlahisoa tse ling nakong ea lits'ebetso tsa karabelo e etsang hore e se ke ea utloa bohloko mongobo ha ka nako e ts'oanang e hlahisa lihlahisoa tse tsitsitseng ntle le matšoenyeho a ho feto-fetoha ha maemo empa e hloka li-solvents tsa tlhaho tse khetholloang ke polarity e matla joalo ka dimethyl sulfoxide (DMSO), N,N-dimethylformamide (DMF), jj. Ho feta moo, linako tse atolositsoeng tsa karabelo tse tlohang kae kapa kae pakeng tsa letsatsi le le leng ho fihlela matsatsi a mahlano hangata li hlahisa boima bo tlase ba limolek'hule hangata bo fokotseha ka tlase ho meeli e ka bang 30k g/mol e etsang hore tlhahiso e kholo e be thata ka lebaka la litšenyehelo tse phahameng tse amanang le eona hammoho le matla a sa lekaneng a bontšitsoeng ke li-PHU tse hlahang ho sa tsotellehe lits'ebetso tse tšepisang tse akaretsang ho damping thepa libaka tsa memori ea sebopeho libopeho tsa sekhomaretsi litharollo tsa ho roala foam jj.

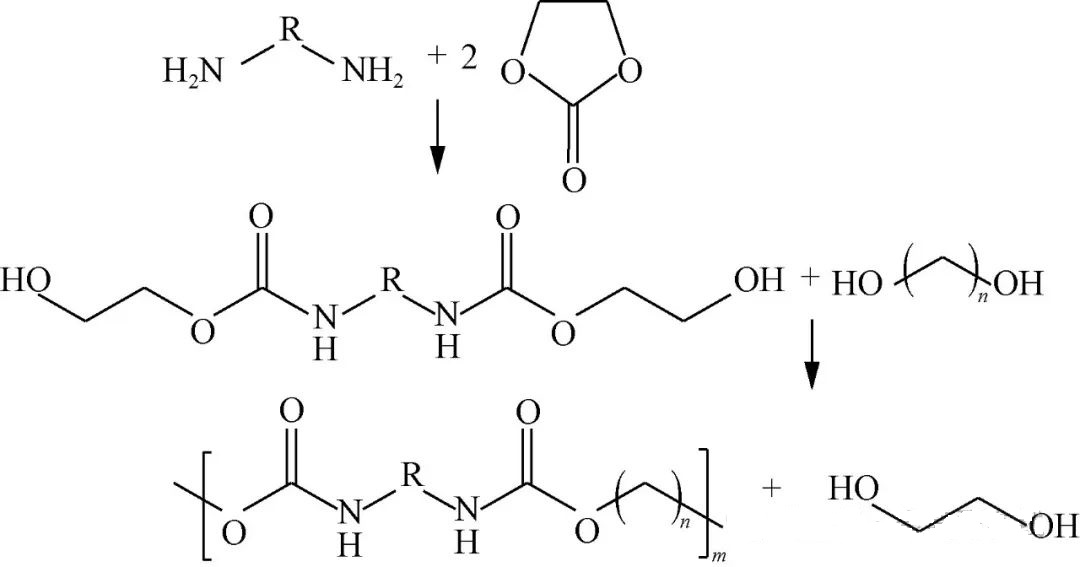

1.2Tsela ea Monocylic Carbonate

Monocylic carbonate e arabela ka ho toba le dicarbamate e hlahang ka diamine e nang le dihlopha tsa qetello tsa hydroxyl tse ka morao ho moo di kopanang ka tsela e ikgethang ya transesterification/polycondensation hammoho le diols qetellong di hlahisa NIPU e tshwanang le ya setso e bontshwang ka pono ho ya ka Setshwantsho sa 2.

Mefuta e mengata e sebelisoang haholo ea monocylic e kenyelletsa li-substrate tse nang le carbonated ea ethylene le propylene moo sehlopha sa Zhao Jingbo Univesithing ea Beijing ea Theknoloji ea Lik'hemik'hale se ileng sa sebelisa li-diamine tse fapaneng tse li arabelang khahlanong le lintho tse potolohileng qalong li fumana li-intermediaries tse fapaneng tsa sebopeho sa dicarbamate pele li tsoela pele ka mekhahlelo ea condensation li sebelisa polytetrahydrofuranediol/polyether-diols tse fellang ka katleho ea ho thehoa ha mela ea lihlahisoa tse bonts'ang thepa e khahlang ea mocheso/mechanical e fihlang holimo libakeng tsa ho qhibiliha tse potolohang ho potoloha sebaka se ka bang 125 ~ 161°C matla a ho tensile a fihlang sehlohlolong sa 24MPa se haufi le 1476%. Wang le ba bang, ka ho tšoanang metsoako e nang le DMC e kopantsoeng ka ho latellana le li-precursors tsa hexamethylenediamine/cyclocarbonated tse etsang li-derivatives tse felisitsoeng ke hydroxy hamorao li ile tsa kenngoa li-acid tsa dibasic tse thehiloeng ho bio joalo ka oxalic/sebacic/acids adipic-acid-terephtalics e fihlellang liphetho tsa ho qetela tse bonts'ang mefuta e akaretsang matla a ho tensile a 13k~28k g/mol a fetohang9~17 MPa e telele e fapaneng35%~235%.

Li-ester tsa cyclocarbonic li sebetsa hantle ntle le ho hloka li-catalyst tlas'a maemo a tloaelehileng, li boloka mocheso o le pakeng tsa hoo e ka bang 80° ho isa ho 120°C, li-transesterification tse latelang hangata li sebelisa litsamaiso tsa catalytic tse thehiloeng ho organotin tse netefatsang hore ts'ebetso e ntle ha e fete 200°. Ho feta boiteko ba condensation feela bo shebaneng le lintho tse kenang ka diolic tse khonang ho iketsetsa polymerization/deglycolysis tse thusang ho hlahisa liphetho tse lakatsehang, li etsa hore mokhoa o be mosa tikolohong, haholo-holo o hlahisang masala a methanol/molecule e nyane-diolic, kahoo o hlahisa mekhoa e meng e sebetsang ea indasteri e tsoelang pele.

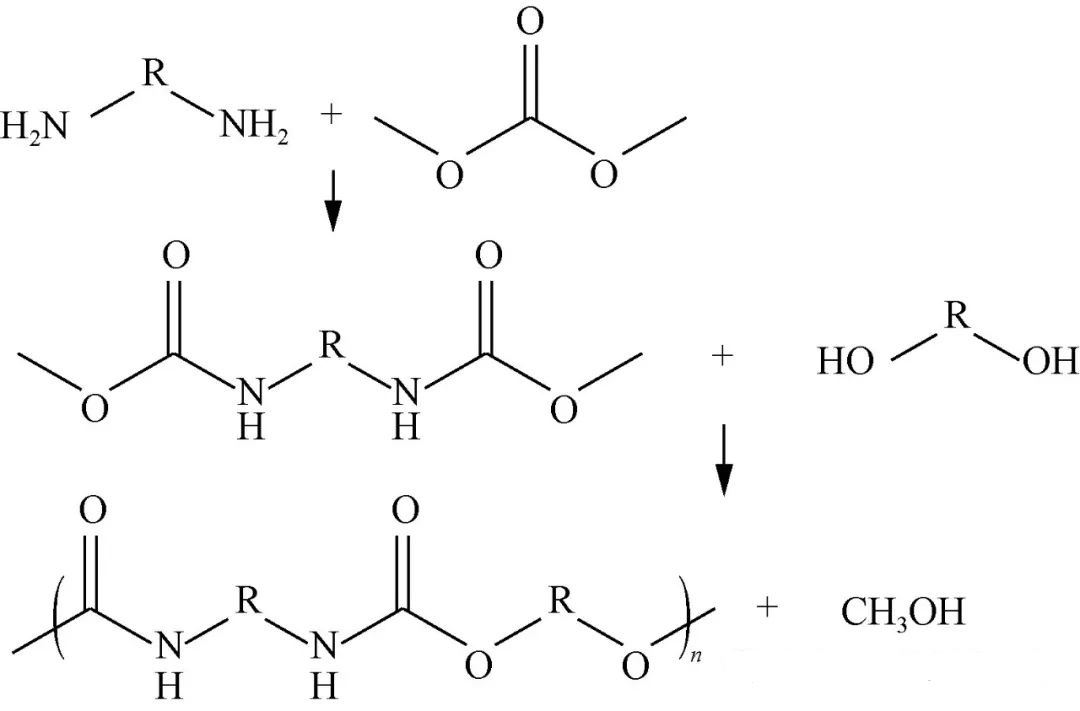

1.3 Tsela ea Dimethyl Carbonate

DMC e emela mokhoa o mong o sebetsang hantle tikolohong/o se nang chefo o nang le likarolo tse ngata tse sebetsang tse kenyeletsang litlhophiso tsa methyl/methoxy/carbonyl tse ntlafatsang liprofaele tsa reactivity tse nolofalletsang haholo likamano tsa pele moo DMC e sebelisanang ka kotloloho le li-diamine tse etsang li-intermediaries tse nyane tse felisitsoeng tsa methyl-carbamate ebe ka mor'a moo liketso tsa ho qhibiliha-kondensate tse kenyelletsang likarolo tse ling tse nyane-katoloso-diolics/polyol tse kholo tse lebisang ho hlaheng ha meaho ea polymer e batloang qetellong e bonts'itsoeng ka ho latela Setšoantšo sa 3.

Deepa le ba bang ba sebelisitse matla a boletsoeng ka holimo ho sebelisa sodium methoxide catalysis ho hlophisa mefuta e fapaneng ea libopeho tse mahareng hamorao ho kenyelletsa likatoloso tse reretsoeng tse fihlang sehlohlolong, metsoako e lekanang ea likarolo tse thata e fihlelang boima ba limolek'hule bo ka bang (3 ~ 20) x 10^ 3g/mol mocheso oa phetoho ea khalase o nkang (-30 ~ 120°C). Pan Dongdong e khethile lipara tsa maano tse nang le DMC hexamethylene-diaminopolycarbonate-polyalcohols tse hlokomelang liphetho tse hlokomelehang tse bonts'ang litekanyo tsa matla a ho tenyetseha tse sisinyehang tsa 10-15MPa e lelefatsang e atamelang 1000%-1400%. Mesebetsi ea lipatlisiso e potileng litšusumetso tse fapaneng tse atolosang ketane e senotse likhetho tse lumellanang hantle le likhetho tsa butanediol/hexanediol ha parity ea nomoro ea athomo e boloka ho lekana ho khothaletsa ntlafatso ea kristale e laetsoeng e bonoang ho pholletsa le liketane. Sehlopha sa Sarazin se lokisitse metsoako e kopanyang lignin/DMC hammoho le hexahydroxyamine e bonts'ang litšobotsi tse khotsofatsang tsa mechini kamora ts'ebetso ho 230℃. Liphuputso tse ling tse reretsoeng ho fumana li-non-isocyante-polyureas tse sebelisang boitlamo ba diazomonomer li ne li lebeletse lits'ebetso tse ka bang teng tsa pente tse hlahang melemo e bapisoang ho feta li-counterparts tsa vinyl-carbonaceous tse totobatsang katleho ea litšenyehelo/mekhoa e mengata ea ho fumana e fumanehang. Tlhahlobo e nepahetseng mabapi le mekhoa ea ho etsa lintho ka bongata hangata e hloka tikoloho e phahameng ea mocheso/vacuum e hananang le litlhoko tsa solvent ka hona e fokotsa melapo ea litšila e fokotsang haholo-holo li-defluent tsa methanol/molecule-small-molecule-diolic tse thehang liparadigms tsa syntheses tse tala ka kakaretso.

Likarolo tse 2 tse bonolo tse fapaneng tsa polyurethane e seng isocyanate

2.1 Polyurethane ea polyether

Polyether polyurethane (PEU) e sebelisoa haholo ka lebaka la matla a eona a kopaneng a tlase a libofo tsa ether ka har'a li-unit tse pheta-phetoang tsa likarolo tse bonolo, ho potoloha habonolo, ho tenyetseha ho babatsehang ha mocheso o tlase le ho hanyetsa hydrolysis.

Kebir le ba bang ba entse polyether polyurethane ka DMC, polyethylene glycol le butanediol e le thepa e tala, empa boima ba limolek'hule bo ne bo le tlase (7 500 ~ 14 800g/mol), Tg e ne e le tlase ho 0℃, 'me ntlha ea ho qhibiliha le eona e ne e le tlase (38 ~ 48℃), 'me matla le matšoao a mang a ne a le thata ho fihlela litlhoko tsa ts'ebeliso. Sehlopha sa lipatlisiso sa Zhao Jingbo se sebelisitse ethylene carbonate, 1, 6-hexanediamine le polyethylene glycol ho etsa PEU, e nang le boima ba limolek'hule ba 31 000g/mol, matla a ho tensile a 5 ~ 24MPa, le ho lelefala ha khefu ea 0.9% ~ 1 388%. Boima ba limolek'hule ba letoto la li-polyurethane tse nkhang hamonate tse entsoeng ka motsoako ke 17 300 ~ 21 000g/mol, Tg ke -19 ~ 10℃, ntlha ea ho qhibiliha ke 102 ~ 110℃, matla a ho thapolla ke 12 ~ 38MPa, 'me sekhahla sa ho hlaphoheloa ha elastic sa bolelele ba 200% bo sa fetoheng ke 69% ~ 89%.

Sehlopha sa lipatlisiso sa Zheng Liuchun le Li Chuncheng se lokisitse 1, 6-hexamethylenediamine (BHC) e mahareng ka dimethyl carbonate le 1, 6-hexamethylenediamine, le polycondensation ka limolek'hule tse nyane tse fapaneng tsa diol tsa ketane e otlolohileng le polytetrahydrofuranediols (Mn=2 000). Letoto la polyether polyurethanes (NIPEU) tse nang le tsela e seng ea isocyanate li ile tsa lokisoa, 'me bothata ba ho kopanya li-intermediates nakong ea karabelo bo ile ba rarolloa. Sebopeho le thepa ea polyether polyurethane (HDIPU) ea setso e lokisitsoeng ke NIPEU le 1, 6-hexamethylene diisocyanate li ile tsa bapisoa, joalo ka ha ho bontšitsoe ho Tafole ea 1.

| Mohlala | Karoloana ea boima ba karolo e thata/% | Boima ba limolek'hule/(g)·mol^(-1)) | Lenane la kabo ea boima ba limolek'hule | Matla a ho thapolla/MPa | Ho lelefatsa nako ea khefu/% |

| NIPEU30 | 30 | 74000 | 1.9 | 12.5 | 1250 |

| NIPEU40 | 40 | 66000 | 2.2 | 8.0 | 550 |

| HDIPU30 | 30 | 46000 | 1.9 | 31.3 | 1440 |

| HDIPU40 | 40 | 54000 | 2.0 | 25.8 | 1360 |

Tafole ea 1

Liphetho tse ho Tafole ea 1 li bontša hore liphapang tsa sebopeho pakeng tsa NIPEU le HDIPU li bakoa haholo-holo ke karolo e thata. Sehlopha sa urea se hlahisoang ke karabelo e ka thoko ea NIPEU se kenngoa ka mokhoa o sa reroang ketane ea limolek'hule ea karolo e thata, se roba karolo e thata ho theha libonto tsa haedrojene tse hlophisitsoeng, e leng se fellang ka libonto tse fokolang tsa haedrojene pakeng tsa liketane tsa limolek'hule tsa karolo e thata le kristale e tlase ea karolo e thata, e leng se fellang ka karohano e tlase ea NIPEU. Ka lebaka leo, thepa ea eona ea mechine e mpe haholo ho feta HDIPU.

2.2 Polyurethane ea Polyurethane

Polyester polyurethane (PETU) e nang le diol tsa polyester e le dikarolo tse bonolo e na le bokgoni bo botle ba ho bola, ho tsamaellana le dimela le thepa ya mechine, mme e ka sebediswa ho lokisa di-scaffolds tsa boenjiniere ba dinama, e leng thepa ya bongaka e nang le menyetla e meholo ya tshebediso. Diol tsa polyester tse sebediswang hangata dikarolong tse bonolo ke polybutylene adipate diol, polyglycol adipate diol le polycaprolactone diol.

Pejana, Rokicki le ba bang ba ile ba sebetsana le ethylene carbonate ka diamine le diol tse fapaneng (1, 6-hexanediol,1, 10-n-dodecanol) ho fumana NIPU e fapaneng, empa NIPU e entsoeng ka tlhaho e ne e na le boima bo tlase ba limolek'hule le Tg e tlase. Farhadian le ba bang ba ile ba lokisa polycyclic carbonate ba sebelisa oli ea peo ea sonobolomo e le thepa e tala, ebe ba kopanya le polyamines e thehiloeng ho bio, ba e koahela ka poleiting, 'me ba e folisa ka 90 ℃ lihora tse 24 ho fumana filimi ea polyester polyurethane e thermosetting, e ileng ea bontša botsitso bo botle ba mocheso. Sehlopha sa lipatlisiso sa Zhang Liqun ho tsoa South China University of Technology se ile sa etsa letoto la diamines le cyclic carbonates, eaba se kopanngoa le biobased dibasic acid ho fumana biobased polyester polyurethane. Sehlopha sa lipatlisiso sa Zhu Jin ho Ningbo Institute of Materials Research, Chinese Academy of Sciences se lokisitse diaminodiol hard segment se sebelisa hexadiamine le vinyl carbonate, ebe polycondensation ka bio-based unsaturated dibasic acid ho fumana letoto la polyester polyurethane, e ka sebelisoang e le pente kamora ho phekoloa ha ultraviolet [23]. Sehlopha sa dipatlisiso sa Zheng Liuchun le Li Chuncheng se sebedisitse adipic acid le di-diol tse nne tsa aliphatic (butanediol, hexadiol, octanediol le decanediol) tse nang le dinomoro tse fapaneng tsa athomo ya khabone ho lokisa di-diol tse tsamaellanang tsa polyester e le dikarolo tse bonolo; Sehlopha sa polyester polyurethane e seng isocyanate (PETU), e rehelletsweng ka palo ya diathomo tsa khabone tsa di-diol tsa aliphatic, se fumanwe ka ho qhibilihisa polycondensation ka prepolymer e thata e sehilweng ka hydroxy e lokisitsweng ke BHC le di-diol. Thepa ya mechini ya PETU e bontshitswe ho Tafole ya 2.

| Mohlala | Matla a ho thapolla/MPa | Modulus e tenyetsehang/MPa | Ho lelefatsa nako ea khefu/% |

| PETU4 | 6.9±1.0 | 36±8 | 673±35 |

| PETU6 | 10.1±1.0 | 55±4 | 568±32 |

| PETU8 | 9.0±0.8 | 47±4 | 551±25 |

| PETU10 | 8.8±0.1 | 52±5 | 137±23 |

Tafole ea 2

Liphetho li bontša hore karolo e bonolo ea PETU4 e na le bongata bo phahameng ka ho fetisisa ba carbonyl, tlamo e matla ka ho fetisisa ea haedrojene le karolo e thata, le tekanyo e tlase ka ho fetisisa ea karohano ea mekhahlelo. Ho kristaletsoa ha likarolo tse bonolo le tse thata ho lekanyelitsoe, ho bontša ntlha e tlase ea ho qhibiliha le matla a ho thapolla, empa ho na le bolelele bo phahameng ka ho fetisisa nakong ea ho robeha.

2.3 Polyurethane e nang le polycarbonate

Polycarbonate polyurethane (PCU), haholo-holo aliphatic PCU, e na le khanyetso e ntle ea hydrolysis, khanyetso ea oxidation, botsitso bo botle ba baeloji le ho lumellana ha bioloji, 'me e na le menyetla e metle ea ts'ebeliso lefapheng la biomedicine. Hona joale, boholo ba NIPU e lokisitsoeng e sebelisa polyether polyols le polyester polyols e le likarolo tse bonolo, 'me ho na le litlaleho tse fokolang tsa lipatlisiso mabapi le polycarbonate polyurethane.

Polyurethane e seng isocyanate polycarbonate e lokisitsoeng ke sehlopha sa lipatlisiso sa Tian Hengshui Univesithing ea Theknoloji ea South China e na le boima ba limolek'hule bo fetang 50 000 g/mol. Tšusumetso ea maemo a karabelo boima ba limolek'hule tsa polymer e ithutiloe, empa litšobotsi tsa eona tsa mechini ha lia tlalehoa. Sehlopha sa lipatlisiso sa Zheng Liuchun le Li Chuncheng se lokisitse PCU se sebelisa DMC, hexanediamine, hexadiol le polycarbonate diols, 'me sa reha PCU ho latela karolo ea boima ba yuniti e pheta-phetoang ea karolo e thata. Litšobotsi tsa mechini li bontšitsoe ho Tafole ea 3.

| Mohlala | Matla a ho thapolla/MPa | Modulus e tenyetsehang/MPa | Ho lelefatsa nako ea khefu/% |

| PCU18 | 17±1 | 36±8 | 665±24 |

| PCU33 | 19±1 | 107±9 | 656±33 |

| PCU46 | 21±1 | 150±16 | 407±23 |

| PCU57 | 22±2 | 210±17 | 262±27 |

| PCU67 | 27±2 | 400±13 | 63±5 |

| PCU82 | 29±1 | 518±34 | 26±5 |

Tafole ea 3

Liphetho li bontša hore PCU e na le boima bo phahameng ba limolek'hule, ho fihlela ho 6 × 104 ~ 9 × 104g/mol, ntlha ea ho qhibiliha ho fihla ho 137 ℃, le matla a ho thapolla ho fihla ho 29 MPa. Mofuta ona oa PCU o ka sebelisoa e le polasetiki e thata kapa e le elastomer, e nang le tebello e ntle ea ts'ebeliso lefapheng la bongaka (joalo ka li-scaffolds tsa boenjiniere ba lisele tsa batho kapa thepa ea ho kenya methapo ea pelo).

2.4 Polyurethane e kopantsoeng e seng isocyanate

Polyurethane e sa tsoakoang le e kopaneng (hybrid non-isocyanate NIPU) ke ho kenyelletsoa ha epoxy resin, acrylate, silica kapa lihlopha tsa siloxane ka har'a moralo oa limolek'hule tsa polyurethane ho theha marang-rang a kenellang, ho ntlafatsa ts'ebetso ea polyurethane kapa ho fa polyurethane mesebetsi e fapaneng.

Feng Yuelan le ba bang ba ile ba sebetsana le oli ea soya ea epoxy e thehiloeng biong ka CO2 ho kopanya pentamonic cyclic carbonate (CSBO), 'me ba hlahisa bisphenol A diglycidyl ether (epoxy resin E51) ka likarolo tse thata tsa ketane ho ntlafatsa NIPU e entsoeng ke CSBO e tiileng ka amine. Ketane ea limolek'hule e na le karolo e telele ea ketane e tenyetsehang ea oleic acid/linoleic acid. E boetse e na le likarolo tse thata tsa ketane, e le hore e be le matla a phahameng a mechini le ho tiea ho hoholo. Bafuputsi ba bang ba boetse ba entse mefuta e meraro ea li-prepolymer tsa NIPU tse nang le lihlopha tsa furan end ka karabelo ea sekhahla sa ho bula ha diethylene glycol bicyclic carbonate le diamine, ebe ba arabela ka polyester e sa tlalang ho lokisa polyurethane e bonolo e nang le ts'ebetso ea ho ipholisa, 'me ba atleha ho hlokomela katleho e phahameng ea ho ipholisa ea NIPU e bonolo. Hybrid NIPU ha e na litšobotsi tsa NIPU e akaretsang feela, empa hape e ka ba le ho khomarela ho betere, ho hanyetsa asiti le mafome a alkali, ho hanyetsa solvent le matla a mechini.

3 Pono

NIPU e lokisoa ntle le tšebeliso ea isocyanate e chefo, 'me hajoale e ntse e ithutoa ka mokhoa oa foam, coating, sekhomaretsi, elastomer le lihlahisoa tse ling, 'me e na le menyetla e mengata ea ts'ebeliso. Leha ho le joalo, boholo ba tsona li ntse li lekanyelitsoe lipatlisisong tsa laboratori, 'me ha ho na tlhahiso e kholo. Ho phaella moo, ka ntlafatso ea maemo a bophelo a batho le kholo e tsoelang pele ea tlhoko, NIPU e nang le mosebetsi o le mong kapa mesebetsi e mengata e fetohile tataiso ea bohlokoa ea lipatlisiso, joalo ka antibacterial, ho itokisa, ho hopola sebopeho, ho thibela malakabe, ho hanyetsa mocheso o phahameng le tse ling. Ka hona, lipatlisiso tsa nakong e tlang li lokela ho utloisisa mokhoa oa ho phunyeletsa mathata a bohlokoa a indasteri le ho tsoela pele ho hlahloba tataiso ea ho lokisa NIPU e sebetsang.

Nako ea poso: Phato-29-2024